Trusted by more than 400+ jewellers globally

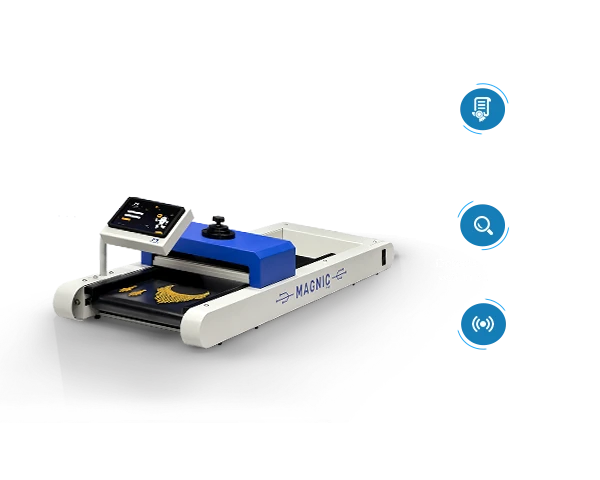

Building a legacy of Intelligent machines

The Team Magnic embraces challenges and love solving the complex engineering problems with our Innovative Solutions. We believe in creating a vibrant ecosystem of intelligent machines that will make our clients more productive and scale up their process capabilities.

VIEW MORE

Few Facts

Our Competencies and Expertise defines our successful journey

Why Magnic?

Our team of Inter-disciplinary engineers are obsessed with constantly finding innovative solutions for the most wanted Industrial requirements. We always strive to look forward with latest developments and trends in technology space. Magnic is the place where your business ambitions and our technology solutions meet together.

A generous mix of Mechanical, Electrical, Electronics and Software Engineers with the Can-Do-Attitude

10000+ Sq. Feet. of our industrial space facilitates us to design, develop and manufacture High-Quality machines.

Our products are manufactured in compliance with ISO 9001:2015 based Quality Management System.

PAN - India level after-sales service network to support our customers on time with assured quality.

Case Studies

Together we grow!

We are here to guide you. our client friendly sales team, helps you in explaining all about the process and your queries

Book a Demo

Subscribe to our Newsletter

Subscribe to our monthly newsletters, to know more about Industry related updates, our new product launches and Actionable insights.